clumping pellet cat litter factory

Understanding Clumping Pellet Cat Litter An Insight into the Factory Production Process

When it comes to maintaining the hygiene of our feline friends, cat litter plays an indispensable role. Among the various types of cat litter available, clumping pellet cat litter has gained popularity among cat owners for its convenience and efficiency. This article explores the process of manufacturing clumping pellet cat litter in factories, shedding light on how these products are made, the materials involved, and their benefits.

Materials Used in Clumping Pellet Cat Litter

The primary materials used in the production of clumping pellet cat litter are bentonite clay, natural plant fibers, and various additives that enhance clumping ability and control odors. Bentonite clay is renowned for its absorbent properties, making it an ideal choice for litter products. It expands upon contact with moisture, forming solid clumps that can be easily scooped out. This characteristic not only simplifies the cleaning process but also helps in maintaining a fresh smell in the litter box.

In some cases, manufacturers may incorporate plant-based materials, such as corn or wheat, to provide an eco-friendly alternative to traditional clay litters. These natural fibers are often biodegradable, appealing to environmentally conscious consumers. To improve the overall performance of the litter, additives may be included to control dust, enhance odor control, or provide additional clumping strength.

The Manufacturing Process

The manufacturing process of clumping pellet cat litter typically involves several key steps

1. Raw Material Sourcing The process begins with the sourcing of high-quality bentonite clay and other natural materials. The chosen materials must meet specific quality standards to ensure optimal performance as cat litter.

2. Grinding The raw materials are then ground into fine particles to enhance their absorbent properties. This step is crucial as the size of the particles can affect the clumping ability and overall performance of the litter.

clumping pellet cat litter factory

3. Mixing and Formulation The ground materials, along with any additives, are thoroughly mixed to achieve a uniform blend. This ensures that each pellet of litter has consistent clumping properties and odor control characteristics.

4. Pelletizing The mixed materials are then fed into a pelletizing machine, which compresses them into small, uniform pellets. This step often involves applying heat and pressure to create strong pellets that withstand breaking down when wet.

5. Drying Once the pellets are formed, they undergo a drying process to remove excess moisture. This is essential to prevent mold growth and ensure the longevity of the litter. The drying process also helps maintain the integrity of the clumping properties.

6. Packaging After drying, the clumping pellet cat litter is cooled and then packaged for distribution. Each package is labeled with essential information, including weight, ingredients, and usage instructions, to assist consumers in making informed choices.

Benefits and Usage

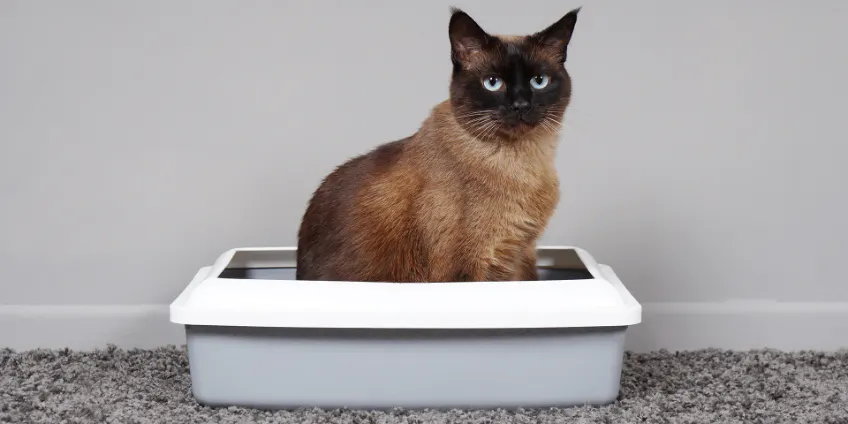

Clumping pellet cat litter offers several advantages. The clumping ability makes it easier for owners to clean the litter box regularly, promoting a healthier environment for their cats. Furthermore, the reduced dust production and odor control properties contribute to an improved indoor air quality, making it a suitable option for households.

For optimal usage, it is recommended to fill the litter box with an adequate layer of pellets and to regularly scoop the clumps at least once a day. Additionally, periodic complete litter box changes are necessary to maintain a fresh and sanitary space for your furry companions.

Conclusion

In summary, the production of clumping pellet cat litter in factories involves a meticulous process of sourcing materials, grinding, mixing, pelletizing, drying, and packaging. This type of litter not only simplifies cat care for owners but also ensures a more pleasant environment for our beloved pets. As we continue to prioritize pet hygiene, the advances in cat litter production reflect our commitment to quality and convenience in pet care solutions.