cat litter sodium bentonite factories

The Role of Sodium Bentonite in Cat Litter Production A Deep Dive into Factories and Processes

Cat litter is an essential product for cat owners, providing a hygienic environment for our feline friends. Among the various materials used for cat litter, sodium bentonite, a type of clay, is the most popular choice due to its excellent absorption properties and ease of use. This article explores the role of sodium bentonite in cat litter manufacturing and offers insights into the factories and processes that bring this essential product to market.

What is Sodium Bentonite?

Sodium bentonite is a naturally occurring clay mineral primarily composed of montmorillonite. This clay is known for its ability to absorb moisture and odors, making it ideal for cat litter. When combined with small pelleted grains, sodium bentonite creates a clumping action, allowing cat owners to easily remove waste while keeping the litter box clean and odor-free. Additionally, sodium bentonite is non-toxic, safe for cats, and environmentally friendly, which further enhances its appeal.

Manufacturing Process

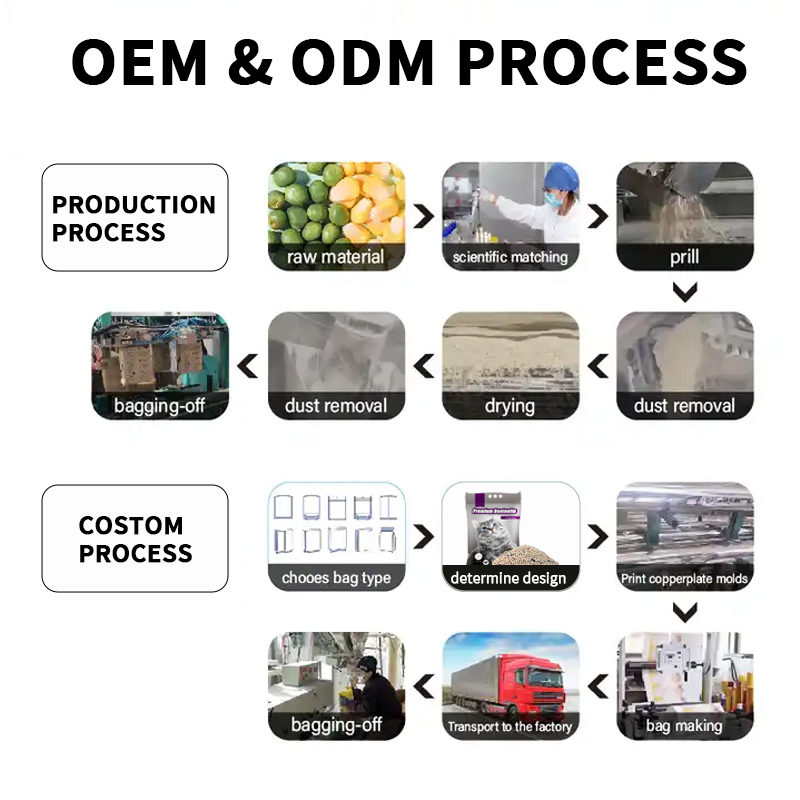

The production of sodium bentonite cat litter involves several key steps, beginning with the extraction of raw materials from natural deposits. Factories typically source sodium bentonite from locations rich in volcanic ash, which has been transformed over millions of years into the clay we use today. The extraction process usually involves open-pit mining, where layers of earth are removed to access the bentonite deposits.

Once extracted, the bentonite goes through a series of processes, including drying, milling, and sieving. Drying is crucial as it reduces the moisture content of the clay, enhancing its absorption capacity. Afterward, the bentonite is milled into fine particles, often mixed with additives such as fragrances or colorants to improve consumer appeal. The final product is then sieved to ensure uniform particle size, which contributes to effective clumping and odor control.

cat litter sodium bentonite factories

Quality Control and Sustainability

Quality control is a critical component of cat litter production. Manufacturers test the bentonite for its absorption capacity, clumping ability, and odor control before it is packaged and sent to market. This ensures that cat owners receive a product that performs effectively, meets safety standards, and fulfills consumer expectations.

Sustainability is also an increasing focus in the production of sodium bentonite cat litter. Many manufacturers are adopting eco-friendly practices, such as using sustainable mining techniques and exploring biodegradable packaging options. Some even leverage alternative recycling methods for used litter to minimize environmental impact.

Conclusion

Sodium bentonite plays a vital role in the cat litter industry, offering unmatched reliability and efficiency for pet owners worldwide. The production of cat litter from sodium bentonite involves careful mining, processing, and quality control to ensure that the final product meets the highest standards. As awareness of environmental impacts grows, the industry is evolving to incorporate sustainable practices, promising a better future for both our pets and the planet.

In conclusion, as cat ownership continues to rise globally, the demand for high-quality cat litter—particularly made from sodium bentonite—will likely increase, reinforcing the importance of this clay in meeting the needs of both consumers and their beloved pets.